Construction time: October 28, 2018 - April 25, 2019

Building area: 56,000㎡

Product features: car batteries with high energy densities

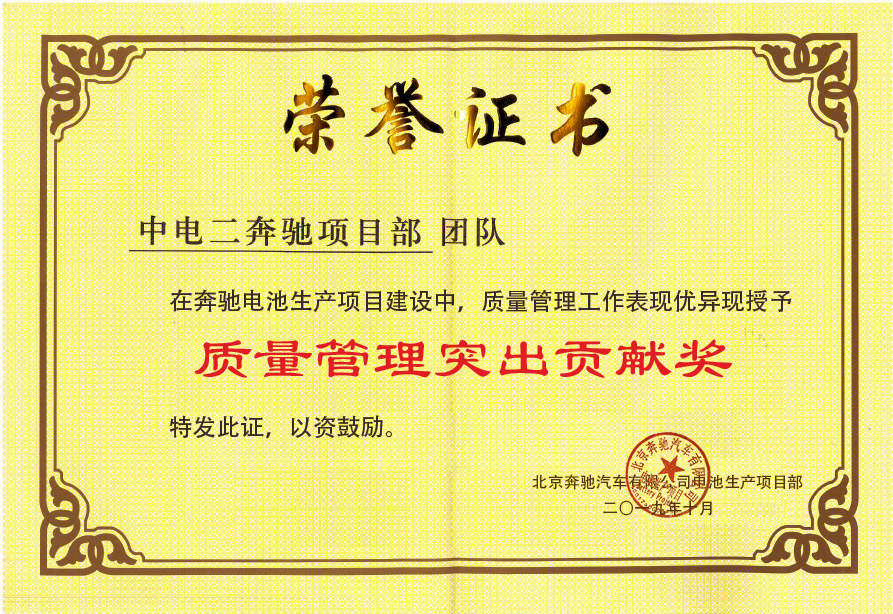

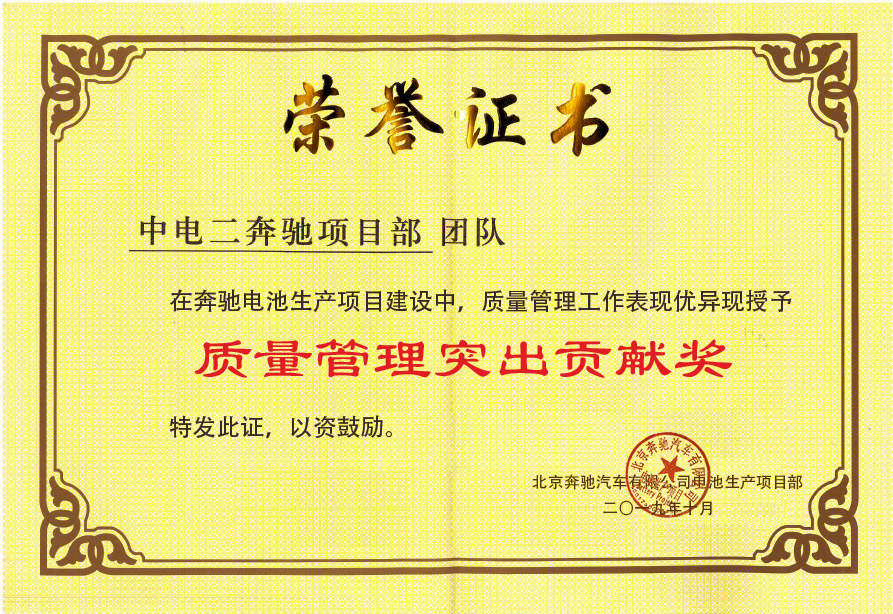

Project awards: Outstanding Contribution Award for Quality Management

Scope of contracting: construction engineering, holder engineering, electrical engineering, compressed air engineering, cooling water engineering, ventilation engineering

Project highlights: Beijing Benz Auto Power Battery Assembly Joint Plant features a total building area of 56,347m2 and covers an area of about 49,000m2. To ensure the excellent safety performance and quality of the power batteries, the Beijing Benz Power Battery Plant strictly follows the Mercedes-Benz integrated global quality management system and adopts many cutting-edge manufacturing processes. In addition, focusing on the manufacturing concept of being "digital, flexible and green", on the basis of technologies such as big data analysis and IoT, this plant has also introduced intelligent manufacturing, intelligent logistics, digital operation, intelligent energy management and other systems, as well as photovoltaic power, solar energy and other clean energies to ensure the efficient, accurate, flexible and environmental friendly production process. At present, as the first Mercedes-Benz power battery plant that has been put into production outside Germany, the power batteries produced by this plant have been successfully delivered internally.

Industry value:the company was mainly responsible for the construction engineering, holder engineering, electrical engineering, compressed air engineering, cooling water engineering, ventilation engineering, etc. of this project.

Aerial view

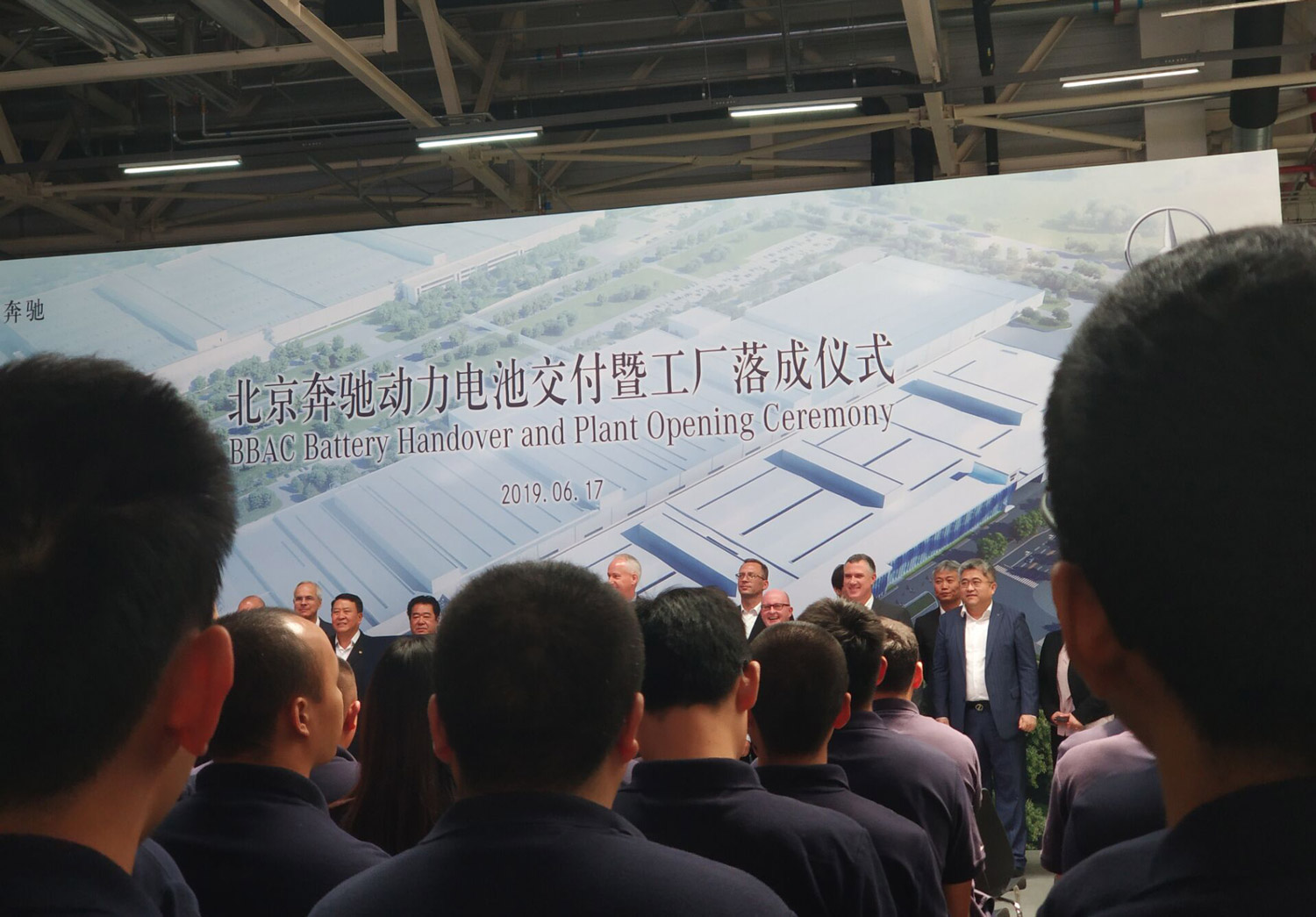

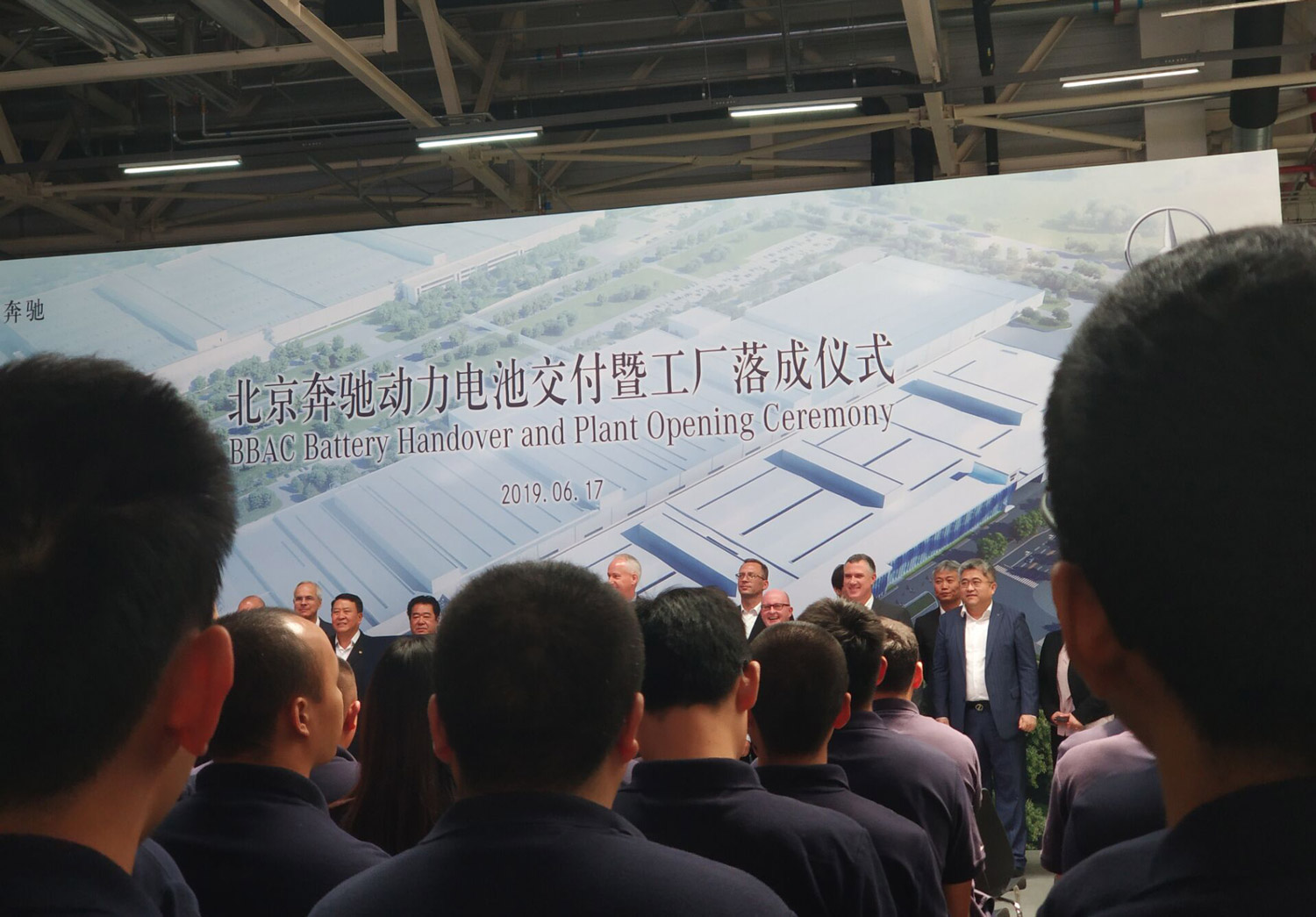

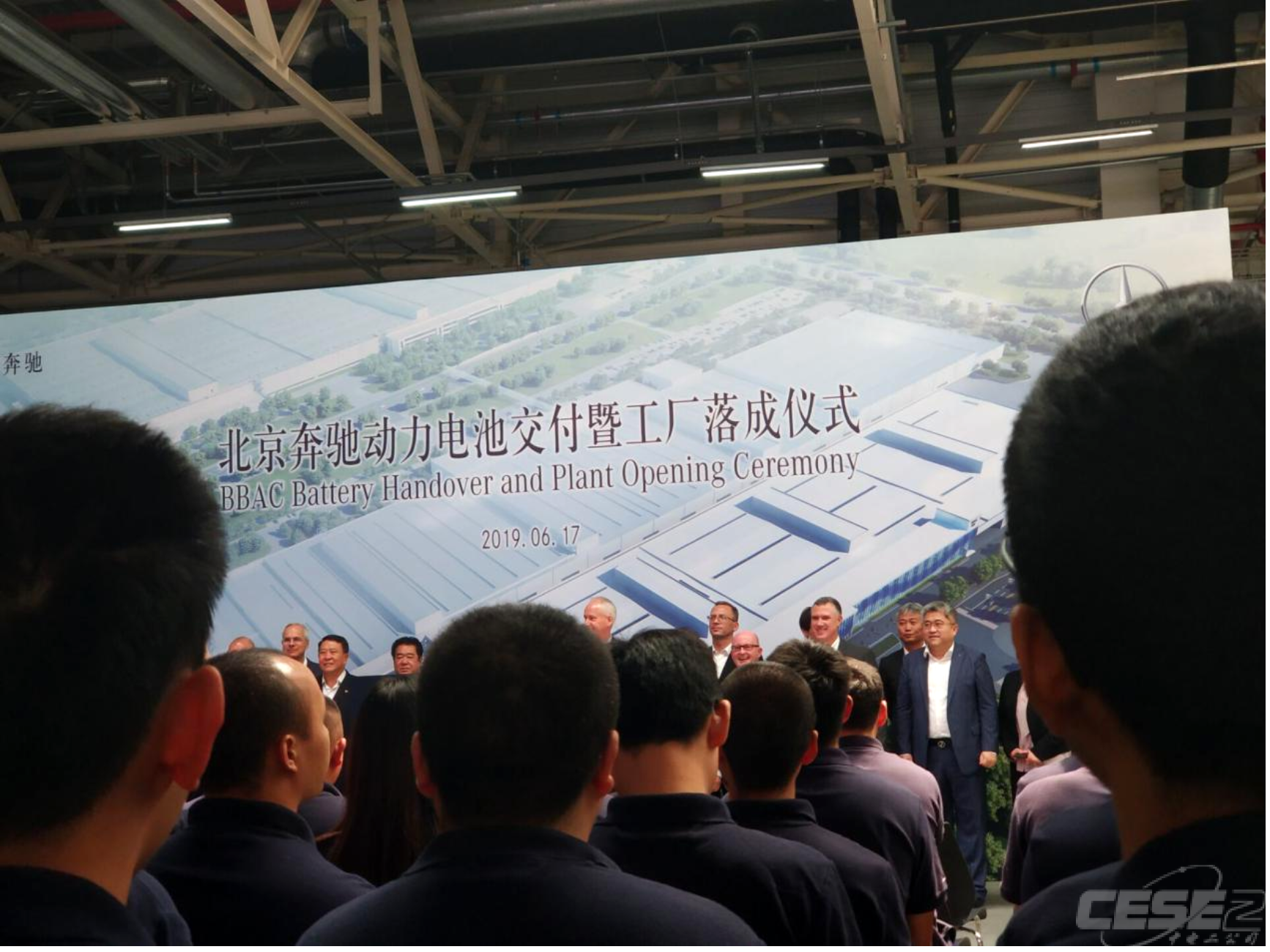

Delivery and production ceremony

Project awards

Outstanding Contribution Award for Quality Management