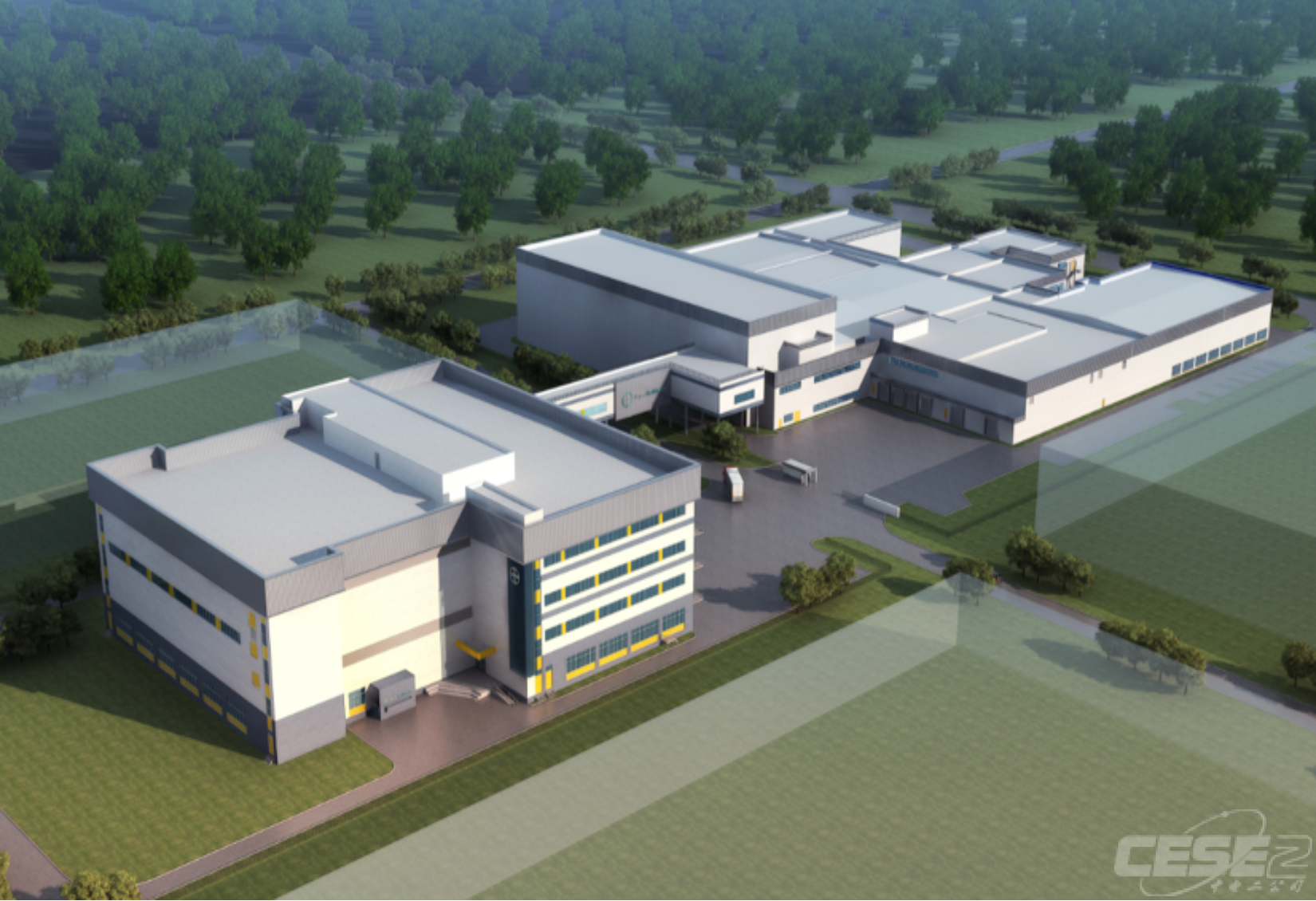

Construction time: August 20, 2020 to September 20, 2021

Building area: 3,774 ㎡

Clean area: 1,650 ㎡

Cleanliness level: Maximum Class D

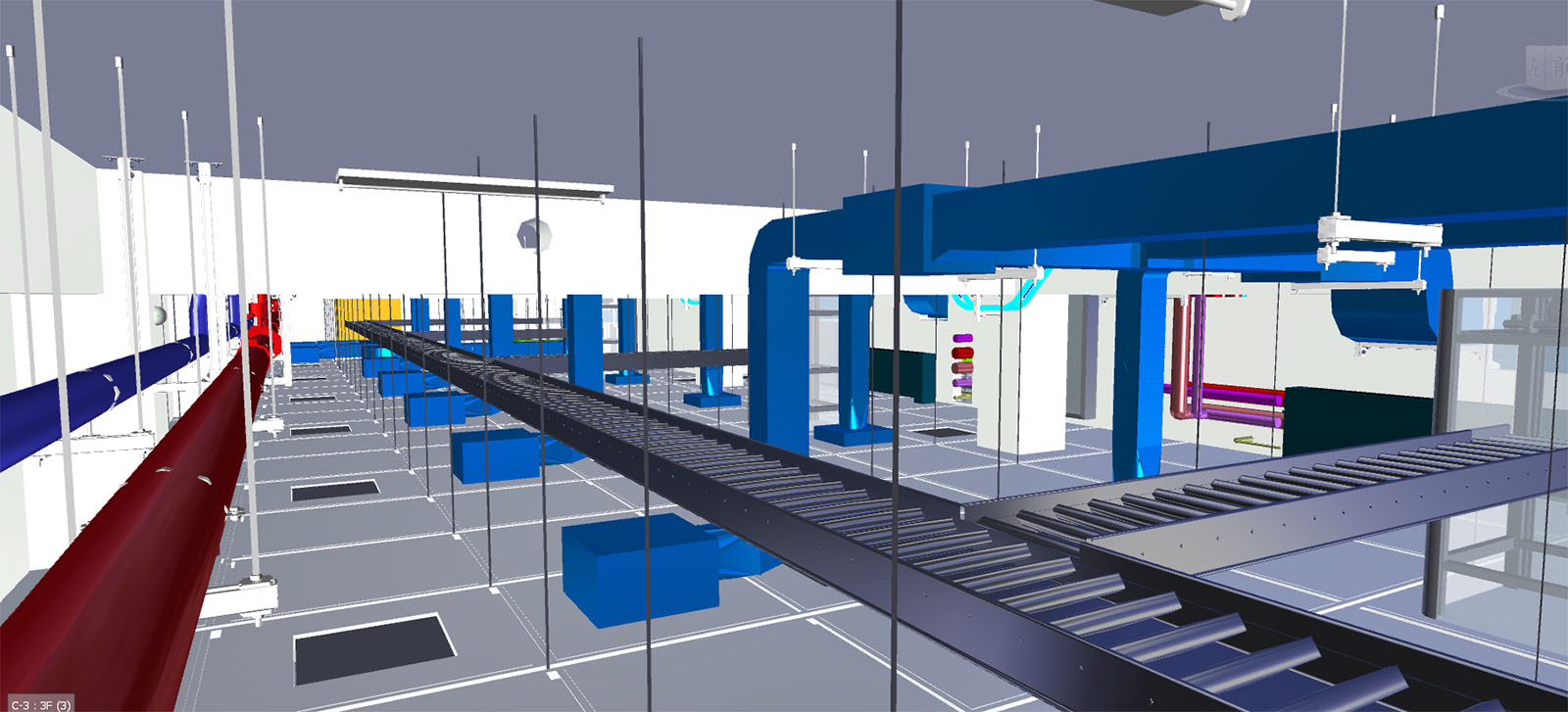

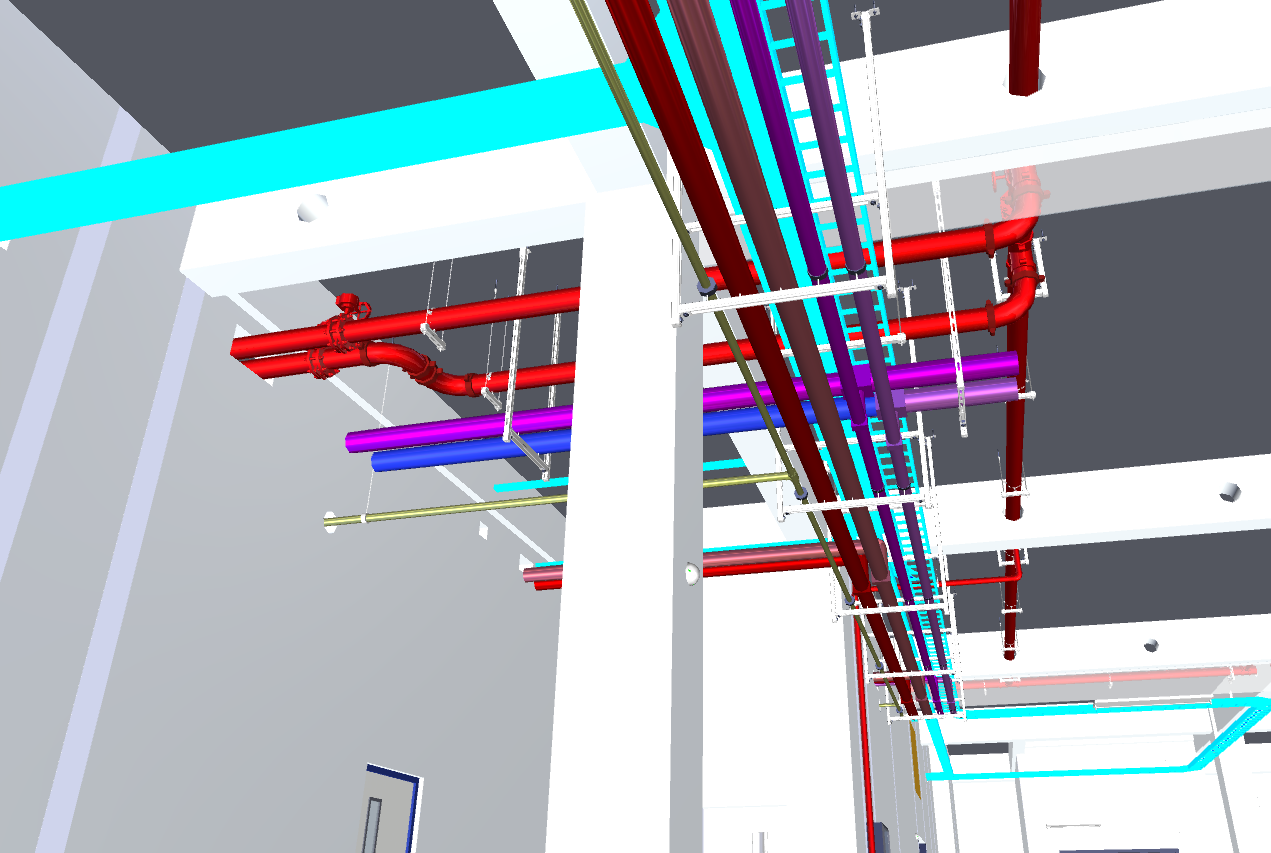

Scope of contracting: Land B F/3 and F/4 electromechanical decoration and steel structure engineering

Project highlights: Beijing factory keeps the stable supply of high-quality therapeutic drugs for chronic disease to the companies such as Glucobay®, Baixintong ® and Bayaspirin ®. Upon the expansion of the factory, the production capacity will be greatly improved to meet the further demand of Bayer's high-quality drugs in the Chinese market in future. The implementation of new projects is of great significance to Bayer's production capacity demand, and Bayer projects are famous for nature of preciseness, and newly built projects will also become benchmark projects in construction.

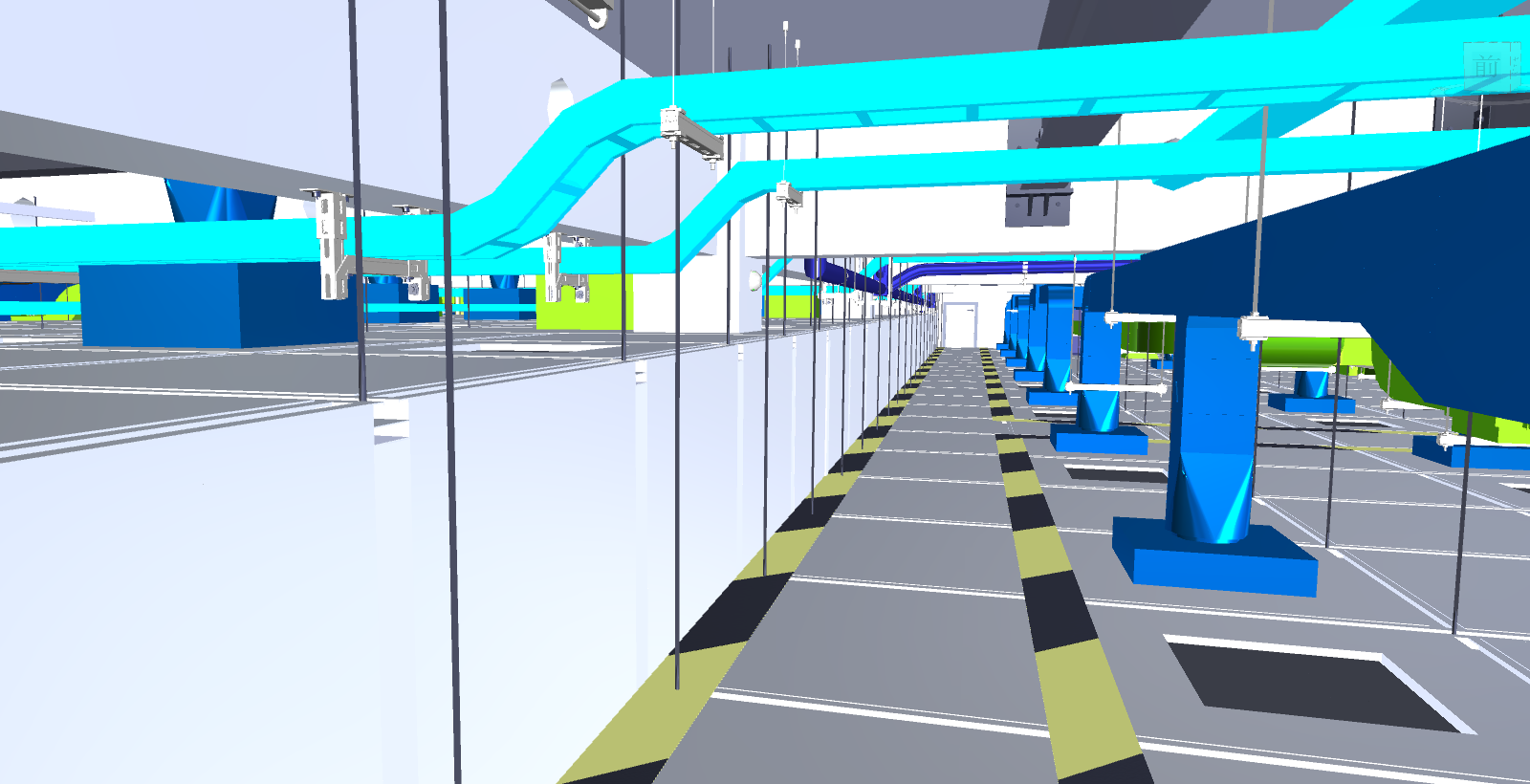

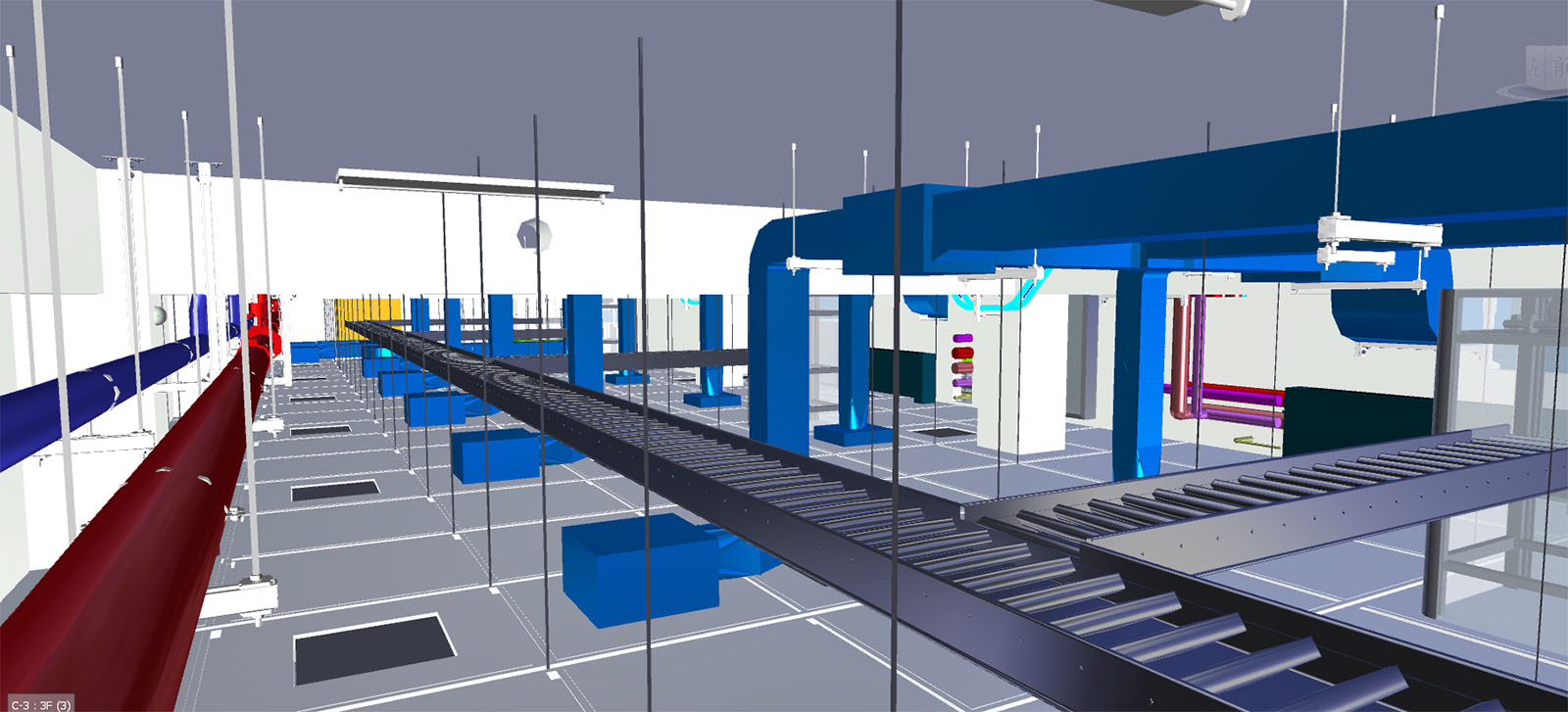

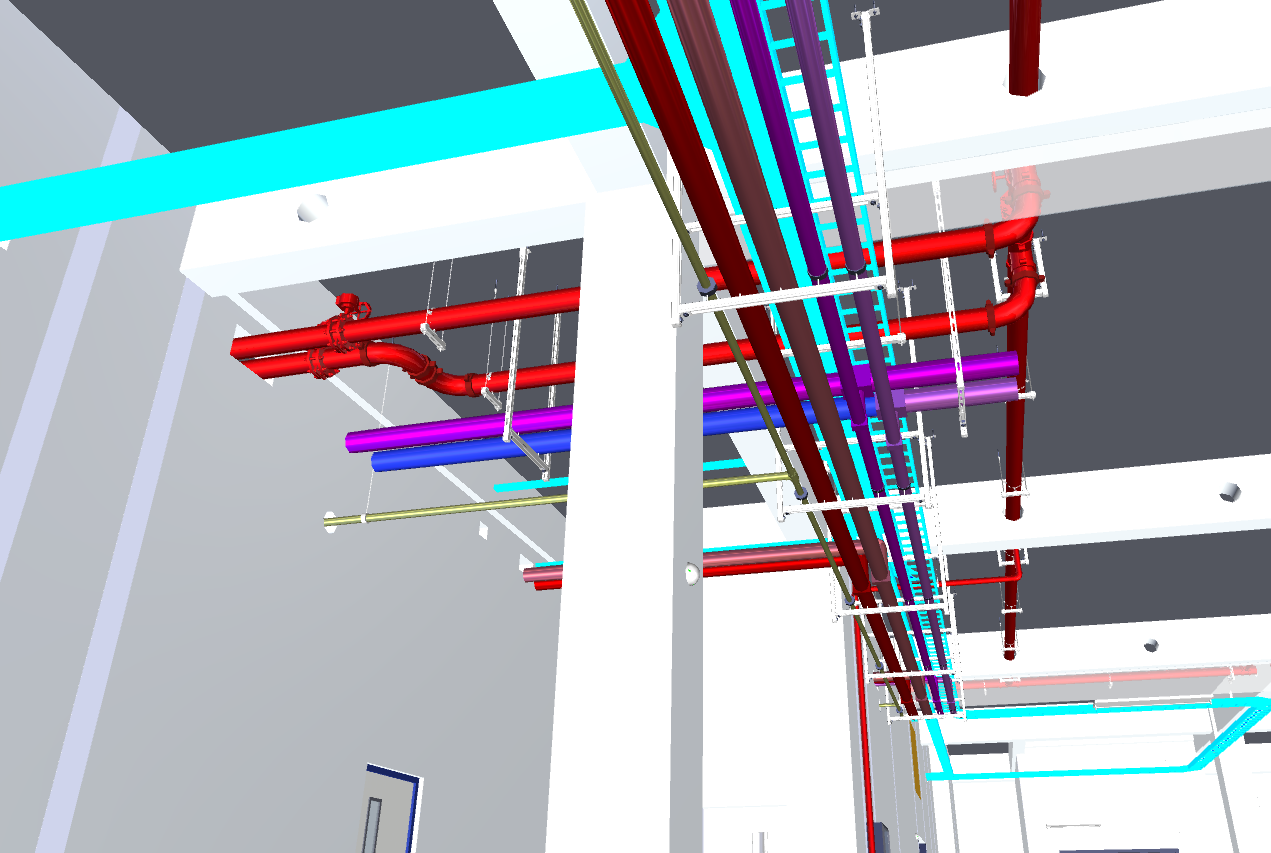

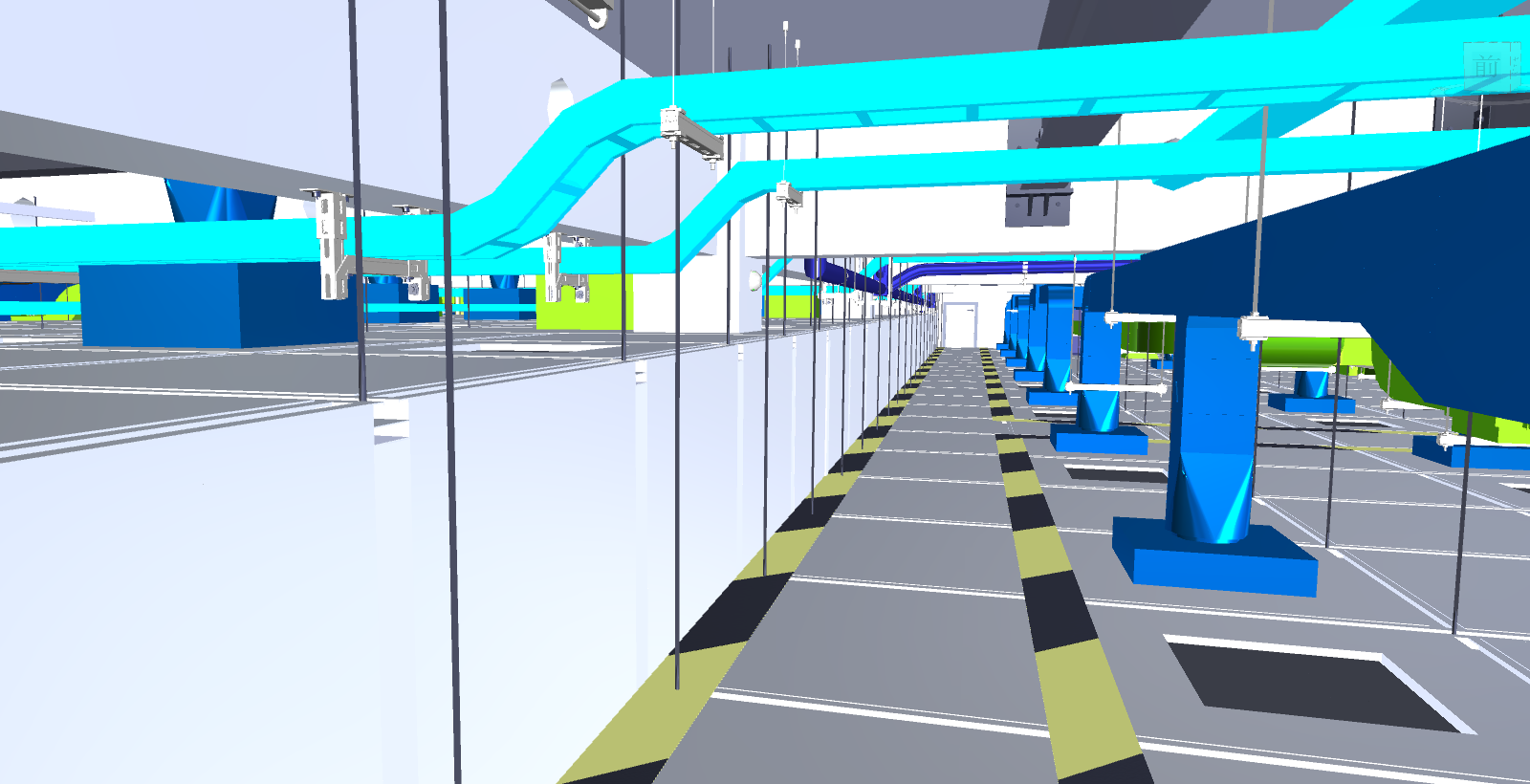

These systems include but are not limited to: KCS cleanroom environment system, cleanroom fresh air treatment system, non-clean area air conditioning system, dust removal system, fire control and smoke exhaust system, (FCU) ventilation and fan coil system, compressed air system, pure water system, steel structure engineering, floor pouring engineering, electrical system, access control monitoring, integrated wiring system, BAS, EMS, fire control and smoke exhaust system, process cooling water system, fire water system, fire power system, domestic cold and hot water system, production cold water system, production softened water system, etc.

Industry value: The newly-built production line is expected to be put into operation by the end of 2022 and upon the completion of the project, increase in annual production capacity of the Beijing factory is expected to be approximately 40%, which highlights its important role as one of the most advanced production bases of Bayer prescriptions in the world.

Aerial view

Commencement ceremony attended by the company leaders